TECHNICAL SPECIFICATION

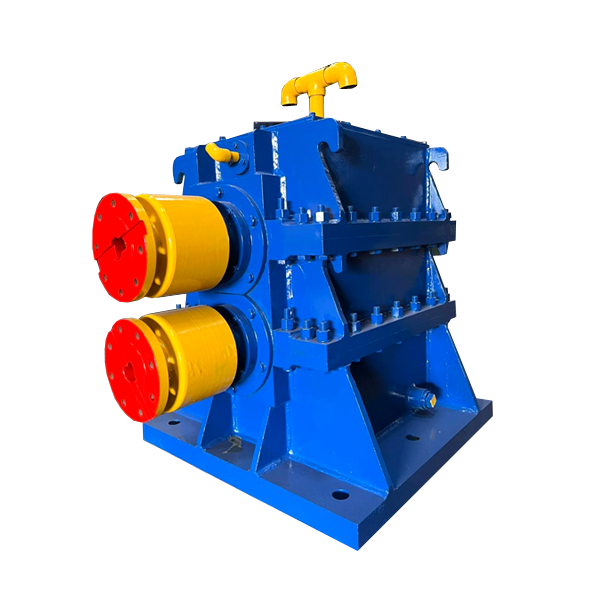

We are specialized in manufacturing and supplying a wide assortment of Reduction Gear Boxes. These are specially designed and developed for the rolling mills of 6” to 36”. Sturdily constructed these Reduction Gear Boxes are one of the first choices of our clients, owing to their high durability and smooth operation. These find their wide application in rerolling mills Fabricated/ Stress relieves.

The presence of latest production facilities like continuous MIG welding stress reliving facility as well as gear box running testing facility also assure of optimum performance values in these gearboxes that are available from 2 hp up to 3000 hp options.

For meeting the variegated requirements of our clients, we are engaged in offering Reduction Gearbox. These gearboxes are offered up to 4 stage to meet the variegated requirements of our clients. Single and double output of the gearboxes are manufactured using forged alloy steel, which is procured from the reliable vendors of the market. Clients can avail these gearboxes in various specifications as per their requirements.

Features / Specification

- The reduction gearbox includes two gears of same size teeth but different diameters

- The number of teeth is kept proportional to the circumference of the gear; greater the diameter more the number of teeth.

- The gear with small diameter makes two revolutions for every one revolution of the gear with larger diameter.

- The amount of torque available on the larger shaft would be twice as much as that on the smaller one.

- Reduction gear box is a closed system in which the amount of input and output power remains constant.

- With the increased torques the speed decrease proportionally.

- Heavy duty and sturdy design support

- Durable construction values that make these suitable to bear overloads

- Complete structure of Gear Box available in MIG welded finish and coming tested by non-destructive weld testing

- All gears Ultrasonic Tested as well as duly hardened and grounded

- All pitches of gears precision checked

Pinion Gear Box

Pinion Stand is fabricated with the purpose to reduce down the input speed to a slower output speed. It is kind of wheel work consisting of a connected set of rotating gears which allows force to transmit or change the motion or torque. The best part about it is that, at the time of manufacturing these Pinion Stand, TS ISPAT PVT LTD can consider client’s demands as well, hence it can be customized in double or triple output shafts as required by the client. Our Pinion Stand have Gear type: Spur, Single & Double Helical Gears upto 2500mm Dia, it’s normal input load range is from 200 H.P. upto 2000 h.p. drives and ideal size range should be between 150mm pcd upto 750mm pcd.

In order to meet the diverse functional needs of clients, generally these stands are made of superior grade hardened raw material, which ensures durability and reliability. These superior quality heavy duty pinion stand with increased power density, are highly useful for designing heavy loads in Rolling Mill Plants, Sugar Mills, Cement Plants, Mines and more.

Features / Specification

- Precision engineered range of pinion gear boxes

- Gearboxes designed to achieve reduction in input speed to slower output speed

- Gearboxes featuring connected set of rotating gears that allow force to be transmitted or motion or torque to be changed

- We can deliver double/triple output shafts as demanded

- Heavy duty and sturdy finish designs that allows bearing overload conditions

- Stress relieved and aligned casing / housing / structure of Gear Box

- All gears ultrasonic tested to ensure superior finish

- All pitches of gears precisely checked

- Casing / housing / structure of the Gear Box is horizontal split type

- Complete structure of Gear Box is MIG Welded which is tested by non-destructive weld testing

SPEED INCREASER CUM PINION STAND

Speed Increaser Gear-Boxes offered comprise highly functional speed increaser gear boxes that are based on latest design support and are developed using experienced team of engineers who combine latest design and technical support in coming up with highly functional gearboxes that are more efficient as well as durable in terms of performance. Here, our expertise lies in manufacturing these speed increaser gear boxes from 2 hp to 3000 hp.

A Speed Increaser is generally installed in Bar Mill in between intermediate Mill Stands to increase the output speed of the rolled product.

Features / Specification

- Ratio :As per Mill Requirement

- Stages :Single/Double Input along with multiple output

- Gears :Forged EN-Series Material with SINGLE/Double Helical

- Bearings :Imported anti friction Spherical roller bearing

- Lubrication :Internal pipes connected with central oil lubrication System