Foundation Lines

Foundation Lines are used for the foundation of Mill Stands, Gear Boxes etc. they are made of Cast Iron. Cast from is used because it can absorb the vibration. it is fully machined and leveled in order to provide proper support and base to the machines standing on it. The basic reason for installing the foundation lines base plates is to strengthen the bottom base

of the machine and to distribute their load uniformly.

Cardan Shaft

Cardan shaft was invented in 16th Century by Girolamo Cardano. It is a mechanical component for transmitting torque and rotation, usually used to connect other components of a drive train that cannot be connected directly because of distance or the need to allow for relative movement between them. It can also accomodate a varying shaft angle Application: Hot Rolling Mill, Cold Rolling Mill, Tube Mill, Textile Mill, Paper Mill, Cement Industries, Mining Industries, Auto Sector, Agriculture Industry etc.

Carden shaft transmits torque from the driving to the driven unit and are proved components of the technical engineering. They enable the connection between two shafts, Which are arranged not in line and allow angular deflection in any plane. Length variations between the shaft end are compensated by splined sliding components.

The overall function of a Cardan shaft can be subdivided in three single functions:

- Torque and speed of Cardan Shaft.

- Changing distance between power input and output of Cardan Shaft.

- Changing angle between power input and output of Cardan Shaft.

Oil Lubrication Systems

Oil Lubrication systems are used to maintain regular supply of ambience temperature oil ta mating parts of Gear Boxes in Rolling Mill. Oil Lubrication Unit is a Pit Hole type box, fabricated out of M.S. plate body and comes complete with all the accessories like: Oil Reservoir, Heat Exchanger, Oil Strainer, Contact Thermometer / Manometer, Duplex Filter, Pressure Gauge, Pressure / Flow Switch, Inlet & Outlet nozzles, lubricating pump unit, Complete Pipeline to & from the Gear Boxes,

Complete with the Control Panel. The system is so designed that the lubricant flows back to the reservoir under the influence of gravity. We manufacture all standard and custom size oil lubrication systems based on the LPM etc.

Hydraulic Pusher

Our esteemed clients can avail a wide range of supreme quality hydraulic Pusher from us. These products are especially designed by a team of experts in compliance with the international quality standards. Hydraulic Pusher are widely used in various industry. We can also customize these Hydraulic Pusher as per the exact specifications provided by our clients. We are engaged in offering a wide range of precision engineered Hydraulic Pushers, which are available with stroke length of up to 8000 mm. These are primarily Rolling mill duty, welded construction design hydraulic cylinders which are widely used by steel plant for Re-heating furnace.

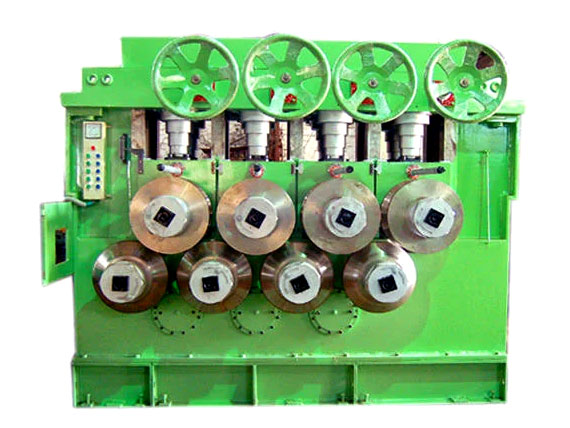

Section Straightening Machine

The machine function is to straighten various deformed products such as Angles, channels, flats,

beams, squares etc. is based on a well proven rotary straightening process. The capacity of the

machine is designated by center of rolls i.e. 230mm, 270mm, 320mm, 410mm, 450, 600mm etc. To

find out the best suitable machine major factors which comes into play are size, shape and yield strength of the section. Robust & Precise Construction of Machine gives High Level Resistance and stability. It has been seen that because of the external or internal force and temperature variation in work processing and transporting, metal profile may bend or get distorted or deformed easily. In order to obtain the high precision product, it should be straightened. With the appearance of straightening machine, the theory of straighten process have gradually become the focus of many manufacturing industries these days.

Discharging Ejector

Discharging Ejector is an Electro-mechanical device which is used to expel the hot material from the re-heating furnace to the Rolling Mill. It has a Mill Housing Type structure with a movable frame and can do both front and side travel for discharging of Hot Material {like Ingots, Billets) from re-heating furnace. It comes complete with heavy stands, rollers, cooling system, wheels for cross travel, gear box and pushing arrangements etc, it uses a square billet of approx. & meter for more] length as the device to push the hot material out of the re-heating furnace. It is manufactured depending on the size and capacity of the re-heating furnace.

Bearing Chock

We are well-known amongst the Bearing Chock Accessories manufacturers for providing high performance Bearing Chocks. These Bearing Chock Accessories are made from top quality metals and developed according to the industrial specifications. Our Bearing Chocks are capable of giving consistent performance in high load working conditions as well.

Characteristics

- Precision in designing

- High tolerance power

- Extremely Efficient

- Low maintenance

Applications

- Rolling Mill Industries

- Supplied in Locating & Non-Locating Types

Forged & Chill Rolls

Ahuja engineering corp. is dedicated to manufacturing Rolls rolling mill, Solid chill rolls, Adamite & other types of rolls. We Manufacture a clear chill Rolls which Utilizes the unique property of iron and Carbon system whereby controlling chemical composition and cooling rate, By Controlled addition of various alloying elements.

Application:- These properties together with the excellent product surface finish these rolls very suitable for application where this

feature is important.