Technical Specification

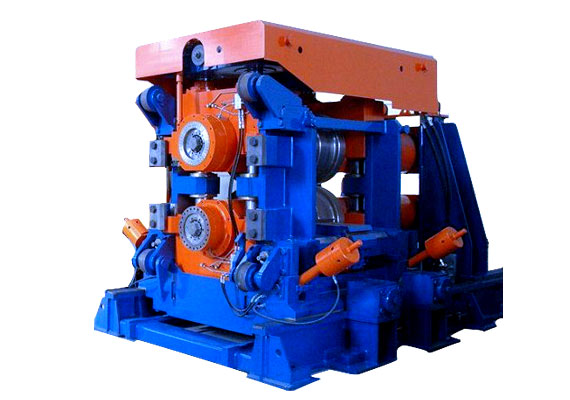

We manufacture and supply complete mill stands for the rolling of Wire rods / TMT / Light Section / Medium Section & Heavy Sections steel and of ferrous and non ferrous Metals, technicalities of our Mill Stands are: –

Type: – 2Hi & 3Hi Horizontal Stands 2Hi Vertical Stands, Universal Stands and Housing Less Stands.

Housing Material Steel Casting / Cast Iron / Steel Fabricated

Size: – 6-30″ i.e. from 150mm PCD to 750mm PCD Mill Bearing Type: – 2 Antifriction Spherical Roller Bearing / Multi Row Bearing / Fibre Bearing / Gun Metal Bush

Salient Features:

- Heavy duty and sturdy design which is suitable to bear overloads

- Complete housing / structure of the Mill Stand is Stress relieved and fully machined

- Genuine and Branded Heavy Duty Antifriction Spherical Roller Bearings / Fibre Bearings are installed after thorough calculation

- Compact and simple design to ensure quick roll change, easy maintenance and to avoid major down time.

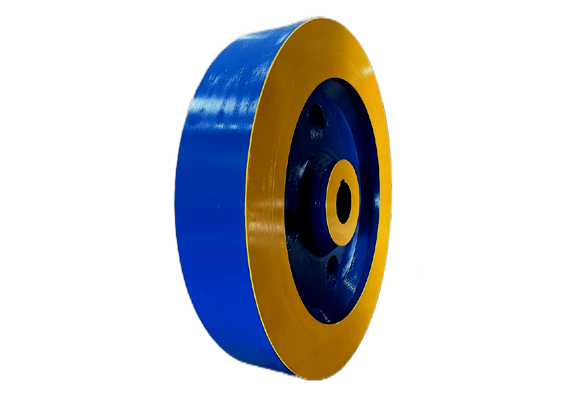

Flywheel

A flywheel is heavy metal wheel attached to a drive shaft, having most of its weight concentrated at the circumference. Main function of flywheel is to reduce speed fluctuation by storing extra energy during part load as kinetic energy and same is released during overloading. By slowly increasing the speed of a flywheel a small motor can stare up energy which enables the motor to perform a function for which it is ordinarily too Small.

Technical Features of fly wheels manufactured by us are: –

- Material:- Cast Steel and Graded Cast Iron

- Weight:- Maximum Upto 30 MT.

- Revolution Range:- 50 RPM to 1500 RPM

- Shaft:- Forged EN-BD or EN-24

- Base Plate / Pedestal:- Fabricated from Mild Steel Prime Plate

- Bearing: Single and Multi-row, depending on Load analysis and speed analysis

- Bearing Block:- Heavy Duty Cast Steel / Cast Iron

- Anchor / Foundation Bolts:- Carbon Steel

- Duly Machined, Bored & Balanced