Roller Guide Box & Twister Pipe

Twist Pipe & Roller guide box are installed at the entry and exit of the Mill Stand in Rolling Mill. They are used for guiding of symmetrical section such as Round, Oval, Square, Flat etc into Mill Stands for Rolling. These are Stainless Steel Casted pipe and boxes which consist of precisely machined Body, Leaf, set of Guides, Nuts & Bolts and Pins & Roller Bearing. The water system for cooling the rolls of the guides is effectively designed and precisely machined in-order to get maximum cooling for the high Alloy Rolls. We manufacture all standard and custom size Twist Pipes & Roller Guide Boxes such as: Morgadshammer Type and open leaf type

Roller Conveyor

One of the Mechanical Material Handling equipment provided by us is the Roller conveyor / table which are used for the transter of hot f cold material from one station to another These are steel fabricated structures and consist of fully machined Seamless pipe / barrel, Alloy Steel Round, Steel Structure, Chain Sprockets, V-belt pulley, Bearings & Bearing Blocks complete with lubrications system. They are driven by Geared Motor or gear boxes and motor with chain and chain sprockets or motor and pulley with v-belts as per the requirement and suitability. We manufacture all standard and custom size conveyors and roller tables such as: Mechanical and Hydraulic ¥ Table, Lifting Table, Transfer Tables, Run Out Table etc.

Universal Spindle

Spindles are used as a device for power transmission and are placed between Couplings. Spindles are manufactured out of forged steel, basically EM-B or EN-2 and are properly machined as per the design and requirement. Our manufacturing range of spindles includes: Palm / Key Groove Type, Star Groove Type

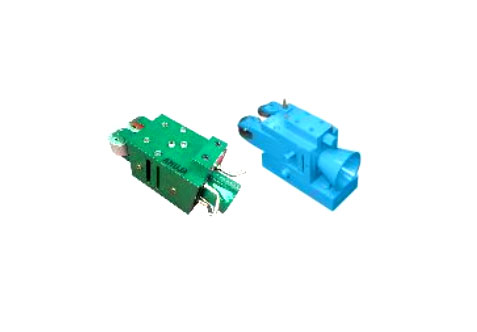

Gear Coupling

Gear coupling is a component used to join two shafts together at their ends, allowing transmission of power. Gear coupling is such an efficient device that makes the shafts unable to disconnect with each other during operation. Joining two pieces of the rotating equipment, this device allows some degree of misalignment.

Ahuja Engineering Corporation is one among the leading manufacturers and suppliers superlative quality Gear Coupling Heavy Duty. It is made in accordance with the industry set standards. Known for its dimensionally accuracy and easy installation, the whole range of high quality gear couplings offered by us is immensely appreciated among the client-base we have accomplished to reap so far.

Features / Specification

- EN-8 and EN-9 material in forging

- Diameter: 6mm to 40 mm

- Material Grade: Fe415, Fe450, Fe500, Fe550, Fe650

- Diameter: 6mm to 40 mm

- Lubrication: Allen bolt, forced greased type

- Suitable for mal-alignment of Shafts up to limited angles

- Can transfer loads up to 3000 HP

- Easy Maintenance

- Excellent Inherent Balance

- Piloted Gear Ideal For Higher Speed And Less Vibration

Universal Couplings

Universal couplings are used to connect the sets of axis and to transfer movement and angular force of mechanical products and have vast application in Hot Rolling Mills.They are classified into types of mechanical, hydraulic and electromagnetic. Mechanical type is the most common one. It is classified into rigid type, flexible type and safe type according to different standards & end user application Rigid type couplings have the main functions of connection and transmission, such as flanged type, sleeve type and clamping type, flexible type couplings have the main functions of connection, transmission, buffering and compensation, such as gear type, membrane type, chain type, universal type and non-metal flexible type. Safe couplings have functions not only as above mentioned, but also overload protection, such as ball type, friction type and pin connected type.

Features / Specification

- Duly machined, Incomparable quality and durable

- Simple design, Easy to maintain

- Easily adoptable and usable

- Versatile design, Tailored to customer’s requirements

- Convey the drive even at 30 Degree Mal-Alignment

- Made from Forged Steel and High Quality Cast Steel